- Free shipping for NZ Customers. All items are available in NZ warehouse

- +64 (0) 212576146

- [email protected]

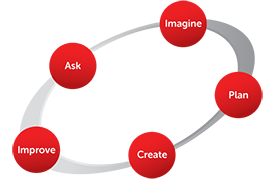

How to perfect the design process?

How to build a sound manufacturing process?

July 3, 2019

Testing process for gauges

August 12, 2019Veethree has been designing instrumentation for over a decade and has the experience to help you perfect your design process. In this blog, Veethree has listed the key areas to focus on for running a successful design process.

PerformanceThe performance of any product is highly dependent on its design process. Having skilled workforce equipped with electronic hardware design and embedded software architecture improves the performance drastically. This helps to meet all specific customer requirements.

Know your customerThe first step we take is to listen to what the customer is asking for, then we question the application. Since we have a lot of experience in this field we can make useful suggestions and customisations to aid our customers.

Design softwareVeethree knows the importance of design software for being able to manufacture consistently and in huge quantity. The need for cutting edge design software like Creo to design products with clarity have provided the better facilities for our workforce.Veethree uses different techniques to ensure customers needs are met, which creates a win win situation for the business and the customers. To sum it all up, a design process can only if successful if the customer is satisfied. Thus, it is important to always put emphasis on the fact that the instrumentation business is invaluable without customer satisfaction.

With nearly four decades of experience in instrumentation, Veethree manufactures and sells close to six million units per annum and has an in-house machine shop apart from the automated manufacturing assembly line for any further customisations. Veethreespecialises in guages. The whole range of gauges and other products can be found here